producing requires are evolving rapidly, necessitating precision and performance to remain aggressive. 1 vital spot driving modernization is using check here personalized fixtures and jigs in creation processes. These crucial instruments make sure the accuracy and efficiency of producing strains, especially when tailored to certain industry requirements. By integrating customized solutions, firms can satisfy special generation problems though acquiring better quality and maximizing output. This site explores how customization in fixtures and jigs is reshaping manufacturing and highlights its Advantages for precision industries.

Table of contents:

Tailoring Fixtures to precise creation specifications

the whole process of building custom made Jigs for Specialized jobs

advantages of Collaborating with suppliers for custom-made alternatives

genuine-earth samples of customized Fixtures maximizing productiveness

Tailoring Fixtures to unique Production Requirements

Fixtures are integral to making sure that elements continue being fixed and effectively aligned throughout the production approach. Tailored fixtures are formulated with precise manufacturing prerequisites in mind, adapting to special merchandise dimensions, workpiece steadiness needs, and operational demands. for instance, suppliers within the automotive or aerospace sectors count on remarkably specialized fixtures to handle sophisticated assembly processes while preserving tolerances inside microns. These customizations be sure that Each and every generation move is repeatable and precise, removing errors which could compromise good quality or security. With precision mechanical components starting to be the benchmark for top-undertaking industries, custom made fixtures function the backbone in their operations.

the entire process of creating Custom Jigs for Specialized Tasks

customized jigs are priceless when output lines require consistent precision and effectiveness. the method starts with being familiar with the producing specifications and operational worries faced by a company. By conducting an in depth design and style consultation, producers can develop jigs that simplify sophisticated production techniques though reducing cycle instances. irrespective of whether for drilling, cutting, or assembly, custom-made jigs deliver regularity to higher-volume production environments. They are typically fabricated utilizing resilient components like metal or aluminum, able to withstanding extensive manufacturing runs with no compromising performance. Sophisticated production systems for instance CAD software program or 3D modeling more streamline the design method, ensuring the jig integrates seamlessly into existing workflows. The end result? extremely effective creation traces that execute duties with unparalleled precision.

great things about Collaborating with brands for Customized options

Choosing to customise fixtures and jigs unlocks a variety of benefits for manufacturers looking to stay competitive. For starters, customization maximizes operational efficiency, as tailor-made alternatives align correctly with the necessities from the producing line. Next, collaboration with experienced brands guarantees specific product collection and structure, translating to long lasting components which might be designed to previous. Lastly, custom methods allow for for faster generation cycles and diminished downtime, as equipment and tooling are optimized for easy functions. Engaging reliable partners like Shenzhen Yongxinglong Industrial advancement Co. for tailor-made jigs and fixtures makes sure superior item high-quality by means of professional craftsmanship and Highly developed production methods. By Operating intently with these experts, firms also gain usage of slicing-edge innovations that increase extended-time period performance.

serious-entire world Examples of personalized Fixtures boosting Productivity

realistic applications of tailor made fixtures and jigs display their important job in modern production units. For example, Shenzhen Yongxinglong collaborates closely with automotive and electronics brands to build specialized welding fixtures. These fixtures be certain seamless alignment of motor vehicle elements during automatic welding operations, resulting in more robust bonds and minimized assembly problems. Similarly, tailor made jigs for electronics producing revolutionize precision assembly, enabling flawless placement of micro-parts. These developments aid enterprises meet up with stringent field expectations by reaching consistent precision. By incorporating tailor made layouts, industries like aeronautics and large equipment can easily decrease cycle moments appreciably, boosting both of those efficiency and profitability.

Customization in fixtures and jigs manufacturing is A vital financial investment for industries searching for excellence. tailor-made remedies from experienced companies like Shenzhen Yongxinglong Industrial growth Co. unlock unparalleled precision and effectiveness, guaranteeing firms can satisfy their output plans when preserving a competitive edge. From lowering cycle situations to maximizing product or service high quality, the advantages of customized fixtures and jigs are simple. have you been wanting to elevate the efficiency of one's manufacturing line? Call Shenzhen Yongxinglong To find out more regarding how their substantial-good quality jigs and fixtures can meet up with your specific prerequisites.

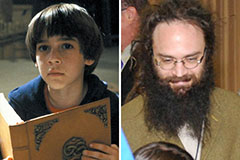

Rick Moranis Then & Now!

Rick Moranis Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Katie Holmes Then & Now!

Katie Holmes Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now!